LEWISTON — About 100 years after it opened in 1850, Bates Manufacturing tried measuring its economic impact by paying workers with $2 bills one week and asking gas stations, groceries stores and doctors’ offices to report back.

The bills popped up everywhere.

Some 5,000 people worked three shifts in the long brick complex, George H. W. and Barbara Bush appeared in the company’s ads and it was taking home awards for honors like “best pantaloon stuffs.”

In the decades after its 1950s heyday, the company changed hands, closed, started anew and stuttered. Twenty years ago, the looms stopped at Bates Mill No. 5, but the legacy is far from over, and the bedspreads go on.

It might be impossible to overstate how much Benjamin Bates, the future Bates College benefactor, shaped the Lewiston of today when he started his textile mill in 1850.

“The Irish came to build the canals (to power the mills) when the potato famine happened and then the French Canadians came down to be the mill workers,” said former longtime Museum L-A Executive Director Rachel Desgrosseilliers. “It became kind of like a family there. They spent as much time there, as part of the community, as they did in their families. It was huge. And the economic impact was huge.”

Over the years, looms turned out material for jeans, airplane wings, hammocks, uniforms, parachutes, flannel and bedding, according to The Bates Association.

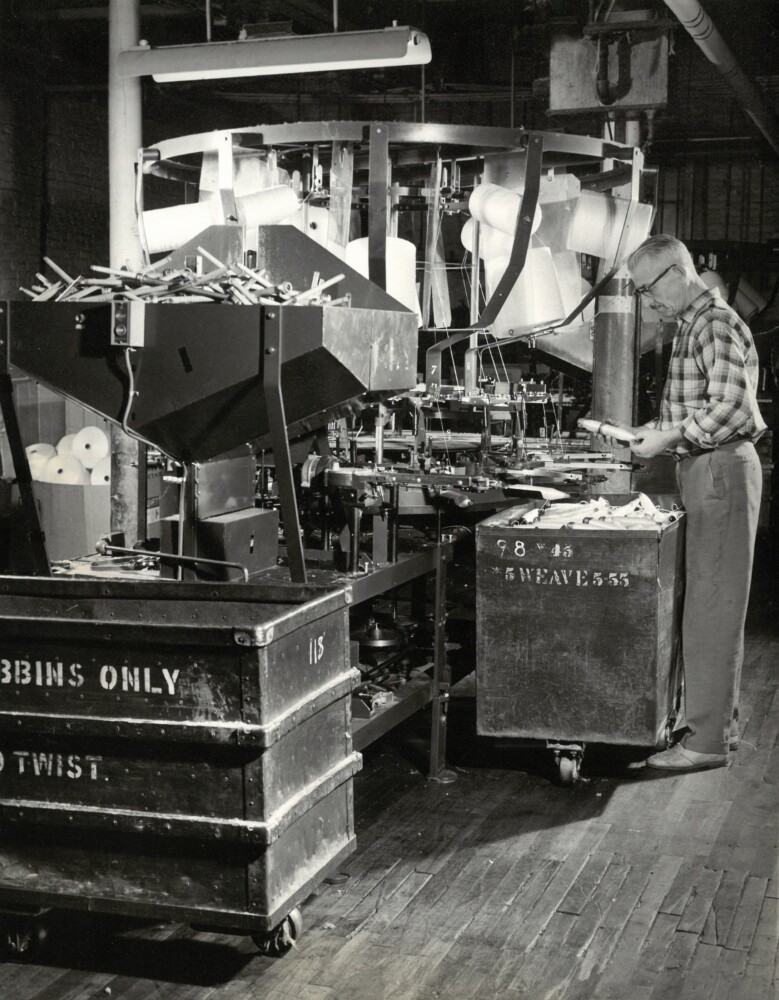

The mill could be really hot in the summer and cold in the winter, and the work was hard, said Danny Fitzsimmons, who started at Bates Manufacturing in 1974 at age 18.

Machinery remains on the second floor of Bates Mill No. 5, once used by Bates Manufacturing. Daryn Slover/Sun Journal Buy this Photo

“I think everybody in my family worked in the mill at one time or the other, all my uncles, my mother, my father,” he said. “I worked in every department there was, including the Pepperell Mill; we had a department there with screen printing. I liked the people, I liked working with my hands.”

Desgrosseilliers vividly remembers visiting her dad in the mills in 1978. He spent 38 years at Bates.

“It was amazing for me to see that. I was never the same after,” she said. “It was 120 degrees in there. He was totally deaf from the noise, we had to yell at each other nose-to-nose to hear each other. He had lint in his eyes, ears, nose and bellybutton. I used to laugh at him when I got home.”

More than 550 people turned out when she held a weaving mill workers’ reunion at the museum in 2005. People stepped off the elevator and hugged. Some found their old equipment in the displays.

One woman told her, “‘I worked on this for 40 years,’ and I went ‘Oh, my goodness,'” said Desgrosseilliers. “Can you imagine doing that repetitive work for 40 years? But she was touching that machine as if it was made of gold, so proud of it, and I’m going ‘Wow.’ It gave people pride of work.”

NEVER GIVING UP ON A DREAM

After coming close before, Bates Manufacturing abruptly shut its doors in 1992, with owners leaving the complex to the city for back taxes. Desgrosseilliers walked through the second floor of Mill No. 5 years later, struck by how swiftly it had been abandoned, “almost like they had left that night to go home and they were going to come back the next morning and they never did. The looms were all set up and everything. The fringe machines were all set up. It was amazing.”

Old looms, once used by Bates Manufacturing, remain on the second floor of Bates Mill No. 5. Daryn Slover/Sun Journal Buy this Photo

“Bates Manufacturing actually went through many, many sales to different companies and that was one of the issues; they kept trying to sell to somebody else to make it better,” she said. “I was speaking to one of the employees that worked closely with some of the management, one of the key things that happened, everyone was saying, ‘It was all the fault of overseas, everything went overseas,’ but not necessarily. They said one of the key things Bates Manufacturing didn’t do, that our mills didn’t do, is they didn’t keep up and upgrade their machinery, so they couldn’t keep up with the new ways of doing things.”

A smaller company, Bates of Maine, started up on the first floor of Mill No. 5. In 2001, down to 119 employees, it closed too, and the looms stopped.

Fitzsimmons got a job in peer support, helping longtime co-workers decide what was next.

“A lot of people did not even have high school diplomas at that time,” he said. “You got out of school, you went to work, you got a job. Schooling was the last thing on a lot of people’s minds. They wanted to work, they needed the money.”

Old looms, once used by Bates Manufacturing, remain on the second floor of Bates Mill No. 5. Daryn Slover/Sun Journal Buy this Photo

In 2002, former Bates of Maine President Fred Lebel struck out on his own, founding Maine Heritage Weavers and ultimately saving Bates Manufacturing’s legacy.

Now headquartered in Monmouth and led by his daughter, Linda Cloutier, the company’s top seller is Martha Washington’s Choice, the same bedspread Bates Manufacturing debuted in 1940. (It was George Washington’s Choice back then; the name changed for corporate and trademark sake.)

Out of Bates’ ashes, success: In 2020, Maine Heritage Weavers had its best year ever, adding looms and, at the start of 2021, adding jobs.

“My grandfather always believed in Bates,” said Bianca Cloutier, Lebel’s granddaughter and vice president of sales and marketing. “He was there for a lot of the times of struggle, but I think Bates is also kind of representative of the struggle that American manufacturers felt, especially in the last quarter of the the 20th century. He knew the fine craftsmanship behind all these products, he knew the people behind them . . .

“He just never gave up on that dream, the idea that we can create things here,” she added.

Bianca Cloutier believes the current interest is being driven by a sense of nostalgia — maybe buyers or their grandparents had the classic Queen Elizabeth or Abigail Adams’ spreads on their beds. A return to vintage fashions and materials by today’s designers. And the draw of made in the USA.

Rolls remain on the second floor of Bates Mill No. 5. They’ve been left in place since the business closed in 1992. Daryn Slover/Sun Journal Buy this Photo

“Bates itself is such a recognized name, especially in New England,” she said. “We find those classic styles still resonate with folks.”

Maine Heritage Weavers, which also operates the Bates Mill Store, has 26 employees, seven of whom, like Fitzsimmons, have roots back to Mill No. 5.

“We’re lucky that the seven represent all areas of production so (we) have the opportunity to ensure the knowledge gets transferred to the next generation first-hand: weave room, stitching, folding, washroom, shipping and management,” Bianca Cloutier said.

Fitzsimmons today works on “every machine there is.”

“They’re temperamental,” he said.

He’s eyeing age 70 for retirement, and training someone now — you can’t teach 40-plus years of loom repair overnight.

Copy the Story LinkSend questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.